News

Why is your pin header connector so expensive?

- Categories:News

- Time of issue:2021-08-05 08:43

- Views:

(Summary description)The pin number of the pin header determines the most important current and information transmission capacity of the connector. In general, the more PIN pins, the more expensive the connector and the better the transmission effect. Of course, you will also find that this is not inevitable, for example, some 12PIN will be more expensive than 16pin or even 24pin.

Why is your pin header connector so expensive?

(Summary description)The pin number of the pin header determines the most important current and information transmission capacity of the connector. In general, the more PIN pins, the more expensive the connector and the better the transmission effect. Of course, you will also find that this is not inevitable, for example, some 12PIN will be more expensive than 16pin or even 24pin.

- Categories:News

- Time of issue:2021-08-05 08:43

- Views:

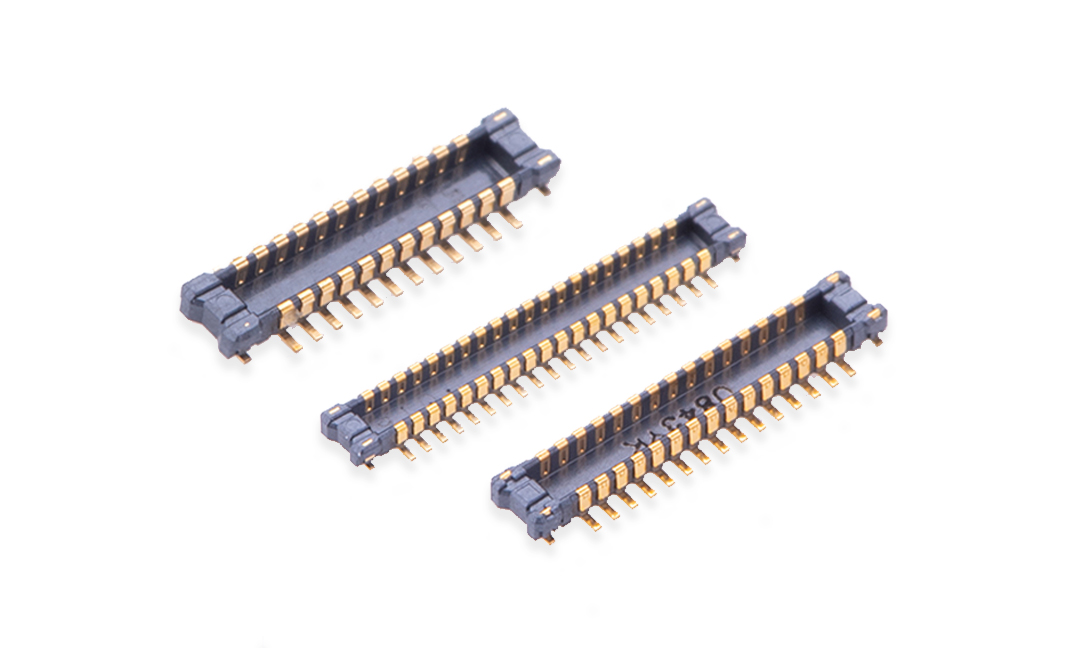

The pin header connector is the most commonly used connector in our daily electronic products. It is used in electronics, electrical appliances, and meters, and has the reputation of a universal connector. The pin number of the pin header determines the most important current and information transmission capacity of the connector. In general, the more PIN pins, the more expensive the connector and the better the transmission effect. Of course, you will also find that this is not inevitable, for example, some 12PIN will be more expensive than 16pin or even 24pin. The main factors affecting the price of pin headers are as follows:

1. Process. Generally speaking, the increase in material cost caused by the increase in the number of pin pins is very small, and it is nothing more than the cost of copper. The real increase is actually the process cost. The more pins, the more complicated the connector. 4pin or 6pin only needs to be injected once, and stamping only needs to punch a row of pieces. But the 24pin pin header connector not only needs the upper row of terminals, but also the lower row of terminals, medium steel sheet, EMC sheath, and GND grounding pin. And the pin needles are densely packed and highly integrated. There are high requirements for stamping and injection molds and processes. If you have to pass usb3.1 gen1 and usb 3.2gen2, you need to do high-frequency simulation analysis. Through high-frequency analysis, see what structure needs to be done, and the process should be matched. The structure is optimized, which increases the difficulty of product production.

2 Shipments. The price of the connector is closely related to the shipment volume. For connectors that are out of stock or need to be customized, a set of molds and automation will cost nearly more than 1 million. The price will slowly decrease after the cost is recovered. If it is only a small batch purchase, many manufacturers will even choose not to accept the order, because this is destined to lose money. Therefore, it is much more cost-effective to choose a manufacturer with inventory to support small-volume purchases than to reopen the mold.

There are a variety of pin header connector models, direct sales from the original factory, complete models, online purchase, and sales starting at 1pcs. Need a connector, click to enter the purchase.

Scan the QR code to read on your phone

Hot News