News

Knowledge about connectors

- Categories:News

- Time of issue:2021-08-04 10:33

- Views:

(Summary description)The connector is a component that our electronic engineering and technical personnel often contact. Its function is very simple: to build a bridge of communication between blocked or isolated circuits in the circuit, so that the current can flow and the circuit can realize the predetermined function. Connectors are an indispensable part of electronic equipment. Observing along the path of current flow, you will always find one or more connectors.

Knowledge about connectors

(Summary description)The connector is a component that our electronic engineering and technical personnel often contact. Its function is very simple: to build a bridge of communication between blocked or isolated circuits in the circuit, so that the current can flow and the circuit can realize the predetermined function. Connectors are an indispensable part of electronic equipment. Observing along the path of current flow, you will always find one or more connectors.

- Categories:News

- Time of issue:2021-08-04 10:33

- Views:

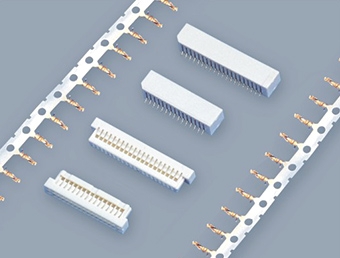

As a key component of current or signal connection, the connector is also an important part of the industrial system. As large as airplanes and rockets, as small as mobile phones and TVs, connectors appear in a variety of different forms, building bridges between circuits or other components, taking on the role of electric current or signal connections. The connector is CONNECTOR. Also known as connectors, plugs and sockets in China. Generally refers to electrical connectors. That is, a device that connects two active devices to transmit current or signal.

The connector is a component that our electronic engineering and technical personnel often contact. Its function is very simple: to build a bridge of communication between blocked or isolated circuits in the circuit, so that the current can flow and the circuit can realize the predetermined function. Connectors are an indispensable part of electronic equipment. Observing along the path of current flow, you will always find one or more connectors.

Connector forms and structures are ever-changing. There are various types of connectors with different application objects, frequencies, power, and application environments. For example, the connectors for lighting on the court and the connectors for hard drives, and the connectors for lighting rockets are quite different. But no matter what kind of connector, it is necessary to ensure that the current flows smoothly, continuously and reliably. In general terms, what the connector is connected to is not only limited to current. In today's rapid development of optoelectronics technology, in the optical fiber system, the carrier of the signal is light. Glass and plastic replace the wires in the ordinary circuit, but the optical signal Connectors are also used in the pathways, and their functions are the same as circuit connectors.

The birth of the connector was conceived from the manufacturing technology of the fighter aircraft. The aircraft in the battle must be refueled and repaired on the ground, and the time spent on the ground is an important factor in the victory or defeat of a battle. Therefore, during World War II, the US military authorities were determined to reduce ground maintenance time and increase combat time due to fighter jets.

They first united various control instruments and parts, and then connected them into a whole system by connectors. When repairing, disassemble the malfunctioning unit and replace it with a new one, and the aircraft will be able to fly into the air immediately. After the war, AT-T Bell Labs successfully developed the Bell telephone system, and then the rise of the computer, communications and other industries gave more opportunities for the development of connectors derived from stand-alone technology, and the market expanded rapidly.

Connector classification

As the structure of the connector is becoming increasingly diversified, new structures and application fields are constantly appearing, and trying to solve the classification and naming problems with a fixed model has become difficult to adapt.

1. According to the nature of use

External connector (for external enclosure), internal connector (for internal enclosure).

2. According to the level of the connector

(1) Component to package interconnection (DEVICE TO PACKING):

Refers to the connection between the IC CHIP and the pin.

(2) The interconnection between the package and the substrate (COMPONENT LEAD TO CIRCCUITRY):

Refers to the connection between COMPONENT and PC board.

(3) Board to board connection (Board To Board):

Refers to the interconnection between the PC board and the PC board.

(4) Subsystem to Subsystem Connection (SUBASSEMBLY TO SUBASSEMBLY)

(5) The connection between subsystems to I/O (SUBASSEMBLY TO I/O PORT).

(6) System to system connection (SYSTEM TO SYSTEM).

3. According to the processing method

Crimp type (Crimp Type), crimp type (I.D.CType), also known as piercing type, solder type (SolderType), zero insertion type (Z.I.F Type).

4. According to the method of use

Wire-to-board connectors, board-to-board connector wires, wire-to-wire connectors, sockets, input and output connectors.

5. According to the form

PCB board connector, flat cable connector, coaxial cable connector, embedded connector, pinch connector, round connector, angle connector, connector for printed wiring board.

6. According to the structure

General connectors, moisture-resistant and waterproof connectors, environment-resistant connectors, air-tight connectors, fire-resistant connectors, and water-resistant connectors.

7. According to working frequency

Low frequency and high frequency (with 3MHz as the boundary).

8. From its versatility and related technical standards, connectors can be divided into the following categories (categories):

①Low-frequency circular connector;

②Rectangular connector;

③Printed circuit connector;

④RF connector;

⑤Optical fiber connector.

Basic performance of the connector

Connector knowledge The basic performance of connectors can be divided into three categories: namely

Mechanical performance, electrical performance and environmental performance.

1. Mechanical behavior

As far as the connection function is concerned, the insertion and extraction force is an important mechanical property. Insertion and extraction force is divided into insertion force and extraction force (extraction force is also called separation force), the requirements of the two are different. There are provisions for maximum insertion force and minimum separation force in the relevant standards, which shows that from the point of view of use, the insertion force should be small (there are low insertion force LIF and no insertion force ZIF structure), and if the separation force is too small, It will affect the reliability of the contact. The plug-in force and mechanical life of the connector are related to the contact structure (positive pressure), the coating quality (sliding friction coefficient) of the contact part, and the dimensional accuracy of the contact arrangement (alignment).

2. Electrical performance

The main electrical properties of the connector include contact resistance, insulation resistance and dielectric strength.

① Electrical connectors with high-quality contact resistance should have low and stable contact resistance. The contact resistance of the connector ranges from a few milliohms to tens of milliohms.

②Insulation resistance is a measure of the insulation performance between the contacts of electrical connectors and between the contacts and the shell, and its magnitude ranges from hundreds of megohms to several thousand megohms.

③ Dielectric strength, or withstand voltage, dielectric withstand voltage, is the ability to withstand the rated test voltage between the connector contacts or between the contacts and the shell.

④Other electrical properties.

Electromagnetic interference leakage attenuation is to evaluate the electromagnetic interference shielding effect of the connector, and it is generally tested in the frequency range of 100MHz~10GHz.

For radio frequency coaxial connectors, there are also electrical indicators such as characteristic impedance, insertion loss, reflection coefficient, and voltage standing wave ratio (VSWR). Due to the development of digital technology, in order to connect and transmit high-speed digital pulse signals, a new type of connector, namely high-speed signal connector, has appeared. Accordingly, in terms of electrical performance, in addition to characteristic impedance, some new electrical indicators have also appeared. , Such as crosstalk (crosstalk), transmission delay (delay), time lag (skew), etc.

3. Environmental performance

Common environmental properties include temperature resistance, humidity resistance, salt spray resistance, vibration and shock resistance, etc.

①Temperature resistance At present, the maximum working temperature of connectors is 200℃ (except for a few high-temperature special connectors), and the lowest temperature is -65℃. When the connector is working, the current generates heat at the contact point, which leads to a temperature rise. Therefore, it is generally believed that the working temperature should be equal to the sum of the ambient temperature and the temperature rise of the contact point. In some specifications, the maximum temperature rise allowed by the connector under the rated operating current is clearly specified.

②The intrusion of moisture resistance will affect the insulation performance of the connection h and rust metal parts. Constant humidity test conditions are relative humidity 90%-95% (according to product specifications, up to 98%), temperature +40±20℃, test time is as per product specifications, at least 96 hours. The alternating damp heat test is more stringent.

③When the salt spray resistant connector works in an environment containing moisture and salt, the surface treatment layer of its metal structural parts and contact parts may produce galvanic corrosion, which affects the physical and electrical properties of the connector. In order to evaluate the ability of electrical connectors to withstand this environment, a salt spray test is specified. It hangs the connector in a temperature-controlled test box and sprays it with compressed air with a specified concentration of sodium chloride solution to form a salt spray atmosphere. The exposure time is specified by the product specification and is at least 48 hours.

④Vibration and shock Vibration and shock resistance are important properties of electrical connectors. They are particularly important in special application environments such as aviation and aerospace, railway and road transportation. It is used to test the robustness of the electrical connector’s mechanical structure and reliable electrical contact. An important indicator of sex. There are clear regulations in the relevant test methods. In the shock test, the peak acceleration, duration and shock pulse waveform, as well as the interruption time of electrical continuity should be specified.

⑤Other environmental performance According to the requirements of use, other environmental performances of the electrical connector include sealing (air leakage, liquid pressure), liquid immersion (resistance to specific liquids), low air pressure, etc.

The basic structure of the connector

The basic structural parts of the connector include ① contact; ② insulator; ③ shell (depending on the type); ④ accessories.

1. Contacts

It is the core part of the connector to complete the electrical connection function. Generally, a contact pair is composed of a male contact piece and a female contact piece, and the electrical connection is completed by the insertion of the female and male contact pieces.

The male contact is a rigid part, and its shape is cylindrical (round pin), square cylinder (square pin) or flat (insert piece). The male contact is generally made of brass or phosphor bronze.

The female contact piece, the socket, is the key part of the contact pair. It relies on the elastic structure to be elastically deformed when it is inserted into the pin to generate elastic force and form close contact with the male contact piece to complete the connection. There are many types of jack structures, including cylindrical (split, necking), tuning fork, cantilever type (longitudinal slot), folding type (longitudinal slot, 9-shaped), box-shaped (square jack) And the hyperboloid wire spring jack and so on.

2. Insulator

The insulator is also often called the base or the insert. Its function is to arrange the contacts at the required position and spacing, and to ensure the insulation performance between the contacts and between the contacts and the housing. Good insulation resistance, withstand voltage performance and easy processing are the basic requirements for selecting insulating materials to be processed into insulators.

3. Shell

Also called shell, it is the outer cover of the connector. It provides mechanical protection for the built-in insulating mounting plate and pins, and provides the alignment of the plug and socket when mating, and then fixes the connector to the device.

4. Accessories

The accessories are divided into structural accessories and installation accessories. Structural accessories such as clamp rings, positioning keys, positioning pins, guide pins, connecting rings, cable clamps, sealing rings, gaskets, etc. Install accessories such as screws, nuts, screws, spring rings, etc. Most of the accessories have standard parts and common parts.

Connector characteristics

1. Either the male contact or the female contact is flexible. The mutual connection of the contacts can be used to ensure the circuit connection.

2. The terminal part of the contact has a wiring structure that is easy to implement wires or printed wiring boards. It is for the implementation of welding, encapsulation, holding, through-hole welding and other structures.

3. The contact is fixed at the correct position of the insulator, and the insulator can be used to maintain the voltage insulation resistance between the contacts.

4. It has a coupling structure, which is convenient for the insertion or removal of the contact, and it does not change its position even after vibration or impact.

The future development trend of electronic connector technology

Connectors, as key components for current or signal connections, are also an important part of the industrial system. With the rapid development of personal mobile terminals, household smart electrical appliances, information communication industry, transportation new energy industry, aerospace technology, artificial intelligence, medical electronic equipment and other fields, improvements have been made to connectors in terms of function, appearance, performance, and use environment. High demands.

1. The development trend of micro-miniaturization and integration

In order to meet the requirements of portable, digital and multi-functional electronic devices, as well as production and assembly automation, electronic connectors must undergo product structure adjustments. Products are mainly developed in the direction of small size, low height, narrow pitch, multi-function, long life, surface mounting, etc.

Miniaturization means that the center spacing of electronic connectors (connectors) is smaller, and high density is to achieve a large number of cores. The miniaturization of consumer electronic products requires components to integrate miniaturization, thinness and high performance, which also promotes the development of connector products in the direction of miniaturization and small pitch. The miniaturization of components places higher demands on technology. All this requires a strong foundation of industrial moulding to effectively support.

2. Intelligent development trend

Today is a world of rapid development of information, no matter what kind of information or technology, people's requirements are getting higher and higher. From the rapid development of information communication data, wireless interconnection has come to everyone of us. From the application of smart phones, smart wearables, drones, unmanned driving, VR reality, smart robots and other technologies, the addition of IC chips and The intelligent development of the electronic connector of the control circuit is an inevitable trend, because it will enable the electronic connector to more intelligently grasp the use of electronic equipment, and improve the performance of the connector itself to achieve intelligent wireless bridging.

3. Development trend of high performance

High-speed transmission means that modern computers, information technology and network technology require that the time-scale rate of signal transmission reaches the megahertz frequency band, and the pulse time reaches sub-milliseconds. Therefore, high-speed transmission electronic connectors (connectors) are required.

The high frequency is to adapt to the development of millimeter wave technology, and the radio frequency coaxial electronic connectors (connectors) have entered the millimeter wave working frequency band.

High current is also an important development direction for many electronic connectors (connectors). Although short, light, thin, energy saving and low consumption are the direction of consumer electronics products, the following two aspects determine the evolution of power supply in the direction of large current in many applications. We take common computer CPUs as an example to illustrate the reasons: 1. Computer performance improvement requires the increase of CPU computing speed and the number of required transistors. Therefore, power consumption rises. Under the condition of the same voltage, the current rises in proportion; second, with the advancement of semiconductor technology, the operating voltage of transistors Gradually reducing is conducive to reducing power consumption, but its physical characteristics determine that the reduction ratio of power consumption is less than the voltage. Therefore, the increase in current is also an important indicator to test the high-performance development of electronic connectors.

Anti-signal interference and shielding. When the data transmission speed increases, the influence of capacitance and impedance becomes more obvious. The signal on one terminal will crosstalk to the adjacent terminal and affect its signal integrity. In addition, the grounding capacitor reduces the impedance of the high-speed signal and attenuates the signal. In the new connector design, each signal transmission terminal is separated from each other. Differential signal pairs can achieve this goal well, because each differential signal pair has a ground pin on one side to reduce crosstalk. Usually the first layer is an area with open pins to separate adjacent ground terminals. The next level is the ground shield installed between the rows. The top-level application would include a metal ground structure surrounding each signal terminal. Such a metal shield achieves the best combination of data transmission speed and signal integrity.

Reliability for use in extreme environments and environmental protection. In the modern high-tech industry, there are many connectors that are used under extreme environmental conditions. Under ultra-high temperature, low temperature, vibration, hot and humid environment, and corrosive environment, electronic connectors can be used effectively and normally, which makes the raw materials in the connector There are higher requirements in terms of selection, structural design, and processing technology. New high temperature resistant materials, new electroplating coating process, and more flexible alloy materials make future connectors more adaptable to harsh environments.

4. The appearance is beautiful and fashionable, and more attention is paid to the development trend of humanization

With the continuous development and progress of multimedia and other technologies, the connector is also adapting to the continuous changes of the main body. Connectors With the increasing development of science and technology, a good connector not only has to look more and more beautiful and fashionable, but also has more and more durable materials and more convenient operation. More importantly, the connection design of its core parts is required. cross

More and more refined and sophisticated. In this way, it will not appear that the normal data connector takes a long time and the card slot becomes loose. When it is severe, the data transmission part of the connector will be completely paralyzed, which will greatly hurt the customer's confidence in the purchase of the main product.

Nowadays, the replacement of electronic products and equipment is very fast, making the future development trend of the connector industry toward miniaturization, integration, intelligence, high performance, and humanization are the future development trends. Only in this way can we adapt to the development of the times. Otherwise, it will be eliminated by the market sooner or later.

Scan the QR code to read on your phone

Hot News